Electrospark Deposition Device

T-SPARK TS-250 / 500 / 1000

Applications: Coating

Using cermet electrodes such as WC (tungsten carbide) and TiC (titanium carbide), anyone can easily achieve a high-performance coating layer with the desired properties. T-SPARK’s high-quality coating dramatically improves wear resistance, seizure resistance, corrosion resistance, heat resistance, etc., and therefore is excellent for maintaining molds, machine parts, and jigs and extending their lifespan.

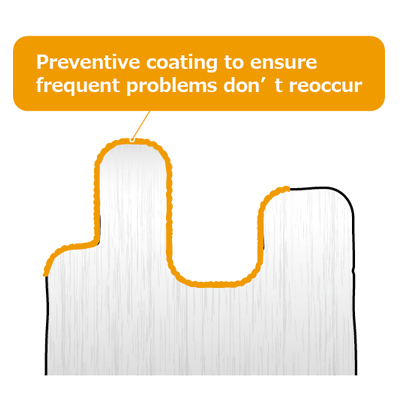

Improve productivity and reduce defective rates by preventive maintenance of aluminum die-casting molds.

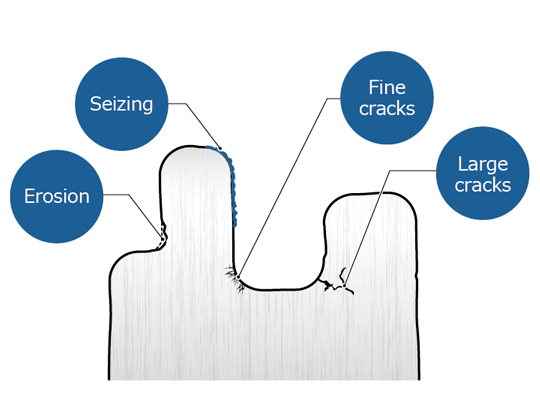

In aluminum die-casting molds, molten aluminum heated to 700 ℃ is injected at high pressure and flows at high speed, causing erosion and wear on the mold surface. Also, insufficient cooling can lead to unwanted depositing. Die-casting molds are frequently heated by the molten aluminum and rapidly cooled by mold lubricants, leading to heat cracks due to this cycle of rapid heating and cooling.

T-SPARK can coat cermet electrodes as preventive maintenance where these problems occur. The coatings prevent erosion, seizing, galling and heat cracks, reduces the need to perform maintenance and improves productivity. In addition, the surface roughness formed by T-SPARK improves the fluidity, prevent flow marks and underfill, and reduce the defective rate of products.

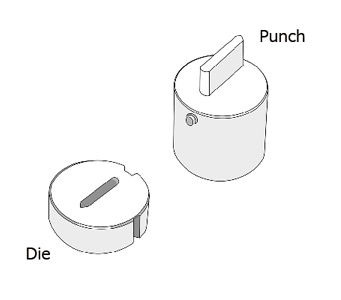

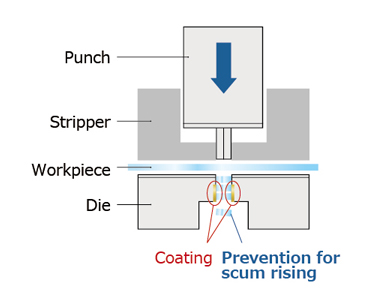

Preventing Scum Rising in Stamping Press Molds

By forming a coating layer in the optimum area on the die side with a coating thickness that takes into consideration the clearance between the punch and the die, scum rising of the punched plate can be prevented. The coating thickness of 2 to 100 μm can be achived by adjusting the electrode material and output.

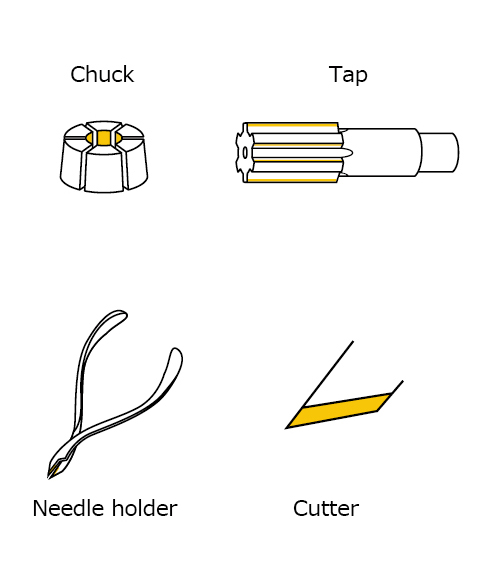

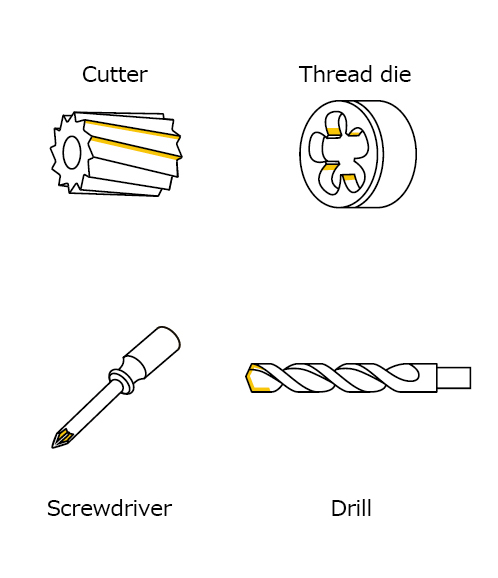

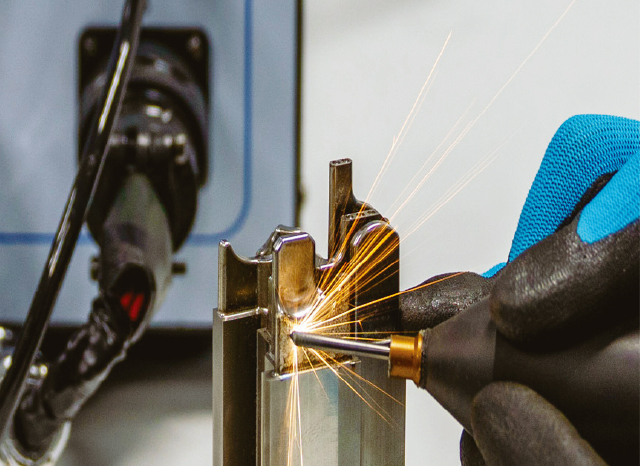

Improved Wear Resistance and Holding Power of Jigs and Tools and Needle Holders

By coating chucks, pipe benders, drills, taps, cutters, dies, screwdrivers, blades, etc., better wear resistance is achieved and the ideal surface roughness improves holding power (grip). The same effect can be obtained by coating the tip of the needle holder used in surgery, and it is applied by domestic and overseas manufacturers.