Electrospark Deposition Device

T-SPARK TS-250 / 500 / 1000 / HB-3300

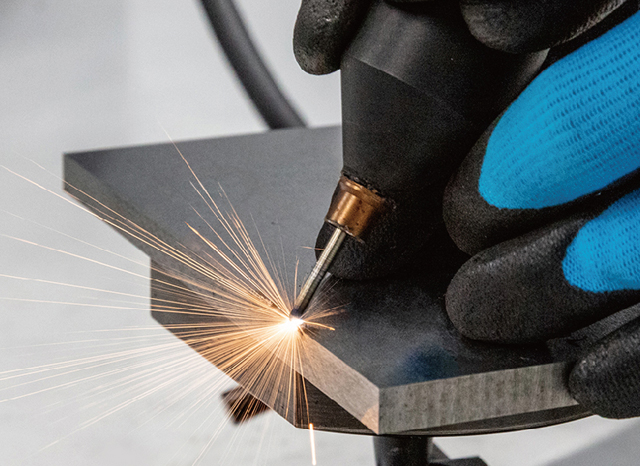

Applications: Cladding

Achieves high-quality cladding repair with excellent on-site workability without heat defects (distortion, under-cuts, changes in hardness, etc.). Anyone can easily repair a wide range of molds, machine parts, jigs and tools of problems such as wear, denting, galling, pin-holes, machining mistakes, etc. It is a must-have item for mold maintenance sites that require quick repair for their customers.

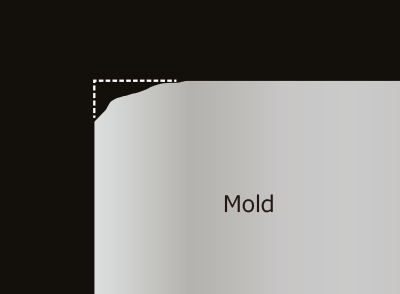

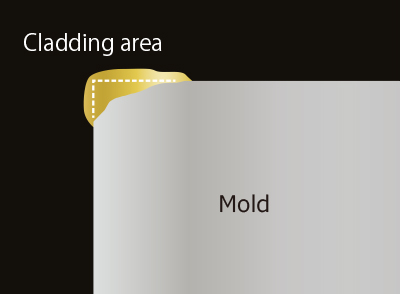

Cladding Repair on the Edge of the Parting Line for Injection Molds

A common problem with plastic injection molds and rubber injection molds is that the edge of the parting line between two molds wears down and burrs can occur on the product. In order to prevent burrs, operators must spend time disassembling the mold and shipping it to a welding shop or manufacturer for cladding repair. This results in higher costs and downtime loss.

With T-SPARK, anyone can easily repair the damage on the edge of the parting line on-site. Since there is no risk of under-cuts due to the low heat input, only a minimum amount of cladding can be achived, allowing for easier finishing by hand.

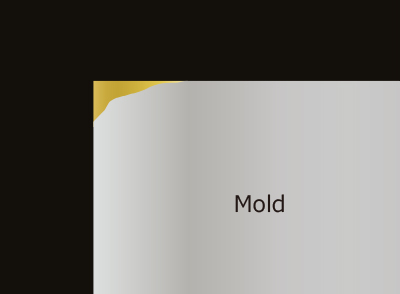

Cladding Repair on the Edge of the Parting Line

Before repair

After cladding

After repair

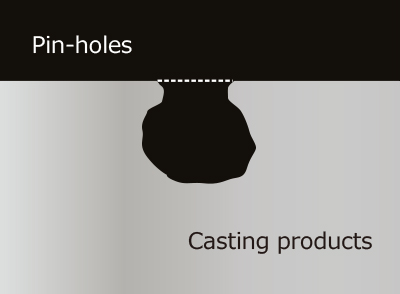

Cladding Repair for Alminum Die-casting Molds

T-SPARK can repair casting defects such as pin-holes, blow-holes, and underfill that occur in aluminum die-casting and other casting products. Blow-holes and pin-holes generated on the machined surface can also be repaired because there are no heat defects (distortion, under-cuts, changes in hardness etc.). T-SPARK can prevent defects in those products, thereby reducing the defective rate.

Pin-hole Repair of Casting Products Through Cladding

Repairs made through cladding avoid causing heat defects (distortion, under-cuts, changes in hardness etc.). Reduces the number of defective products.

Before cladding

After cladding

After repair

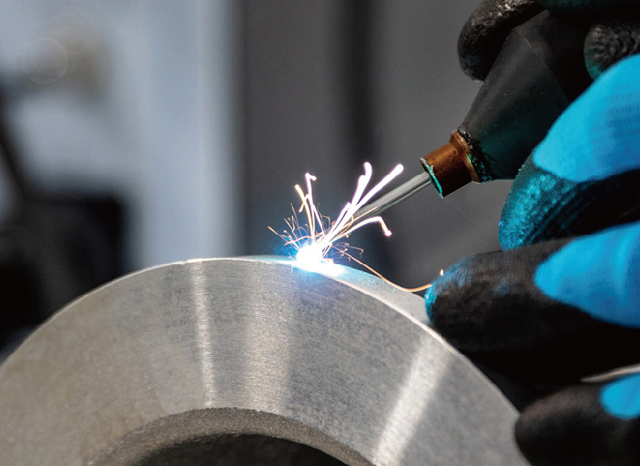

Cladding Repair of Mechanical Parts

Anyone can easily repair the pin-holes, wear damage, galling, dents, etc. that occur on large rolls and shafts on site. If you have T-SPARK at the maintenance site in the factory, you will have many more choices using cladding repair.